¡¡¡¡The water supply and drainage process control system is mainly formed by TiSNet system which includes communication system, industrial TV monitoring system, computer monitoring system, remote pump station control system, disposal-at-sea pump station control system and sewage treatment plant control system and so on.¡¡¡¡

¡¡¡¡The water supply and drainage process control system is mainly formed by TiSNet system which includes communication system, industrial TV monitoring system, computer monitoring system, remote pump station control system, disposal-at-sea pump station control system and sewage treatment plant control system and so on.¡¡¡¡

1£©Communication system

TiSNet chooses the redundant optical-fiber exchanger in line with industrial standards to form the redundant-optical fiber backbone network (100Mbps). With the integration of real-time image network, data monitoring network and language network, the reliability and real-time performance of the system can be assured. Besides a pair of redundant real-time data communication network, TiSNet owns l-an Ethernet-based 100Mbps information communication network to transfer various file data and manage information. It can be connected to other systems conveniently.

2£©Industrial TV monitoring system

This system is composed of the most advanced international hardware and special monitoring software. This is to make sure that all images can be displayed on the TV wall. Replay, video-recording and alarm can be executed simultaneously by utilizing the computer software. It uses low-light sensitive color video camera with a zoom lens so that we can see the equipment and devices clearly through this system. There installed a video controller and a main controller on the workbench in the central control room. They can control and switch the images on the projection screen and the display mode as well as the position and visual angle of the video camera. They can also inspect or supervise on set point the producing area or equipment.

3£©Computer monitoring system

This system is composed of computer, monitoring software and Windows NT/2000 software based on the structure of Operation / Engineer stations are being used. It realizes the control and management of remote equipment through Ethernet. All monitoring and control stations which are redundant form a switching computer LAN (100M) of C/S structure. It can be connected to the urban drainage information center and peripheral water lifting pump stations. The central control room is connected to each sub-control-station through a redundant optical-fiber ring network and the industrial Ethernet switch for transfering data and video simultaneously. The bit rate is 100Mbps.

4£©Field control station with DCS (PLC)

Field control station (redundant) can be operated separately. It controls remote unit or distributing I/O units via Ethernet/BUS and devices with field bus. The main controlled devices employed with three-tier control methods: local control, site control and central control. From high to low, the control levels can be divided into manual control, gang control, remote control and auto control.

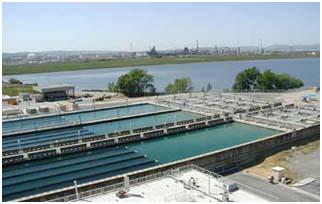

5£©Control systems of pump station, disposal-at-sea pump stations and sewage treatment plants

These systems are composed of high-performance DCS distributed processing units (PLC Controller), site instruments and control devices. They can realize the auto-control within unattended pump stations and sewage treatment plants.